Installation

In order to get satisfactory service and longer life from stainless steel flexible hose, the hoses assembly should be installed in the right manner. The sharp bending a hose assembly, particularly at the welded ends, stressed and twisted mounting and excessive fatigue are main causes of premature failure. See installation chart for correct and incorrect modes.

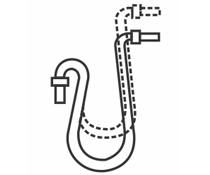

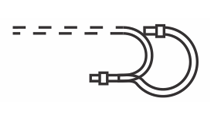

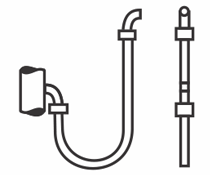

Incorrect

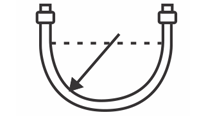

| Dimension the hose adequately |

|

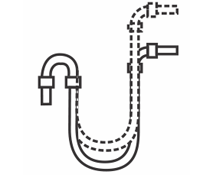

| Avoid excessive bending of the hose |  |

| Do not allow the hose to sag |  |

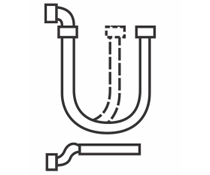

| Do not move the hose obliquely to the installation plane |  |

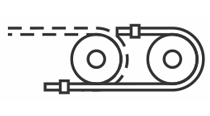

| Avoid torsional twist when fittings are not in line |  |

| Avoid torsion due to Angular movements |

|

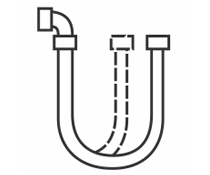

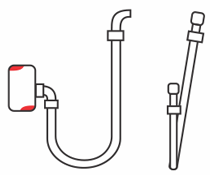

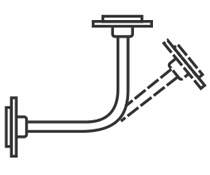

correct

| Take care that the flexible length is not too short |  |

| Use pipe bends |  |

| Use a support |  |

| Movement should be along |

|

| Install in one plane only |  |

| All movements should be only along the axis of the hose |  |